How the Integration of ERP and PIM Systems Enhances Data Management and Company Efficiency

ERP systems (Enterprise Resource Planning) are software solutions that help companies manage and automate business processes, improve efficiency, and maintain a high level of control over the business. Millions of people use ERP systems daily.

According to research agencies like Gartner and IDC, the ERP market continues to grow, and by 2024, the number of companies implementing ERP has increased due to digital transformation and global competition. Large corporations are usually the first to implement ERP systems to manage complex business processes.

Small and medium-sized companies are also adopting ERP systems, driven by the availability of cloud solutions that reduce implementation and maintenance costs.

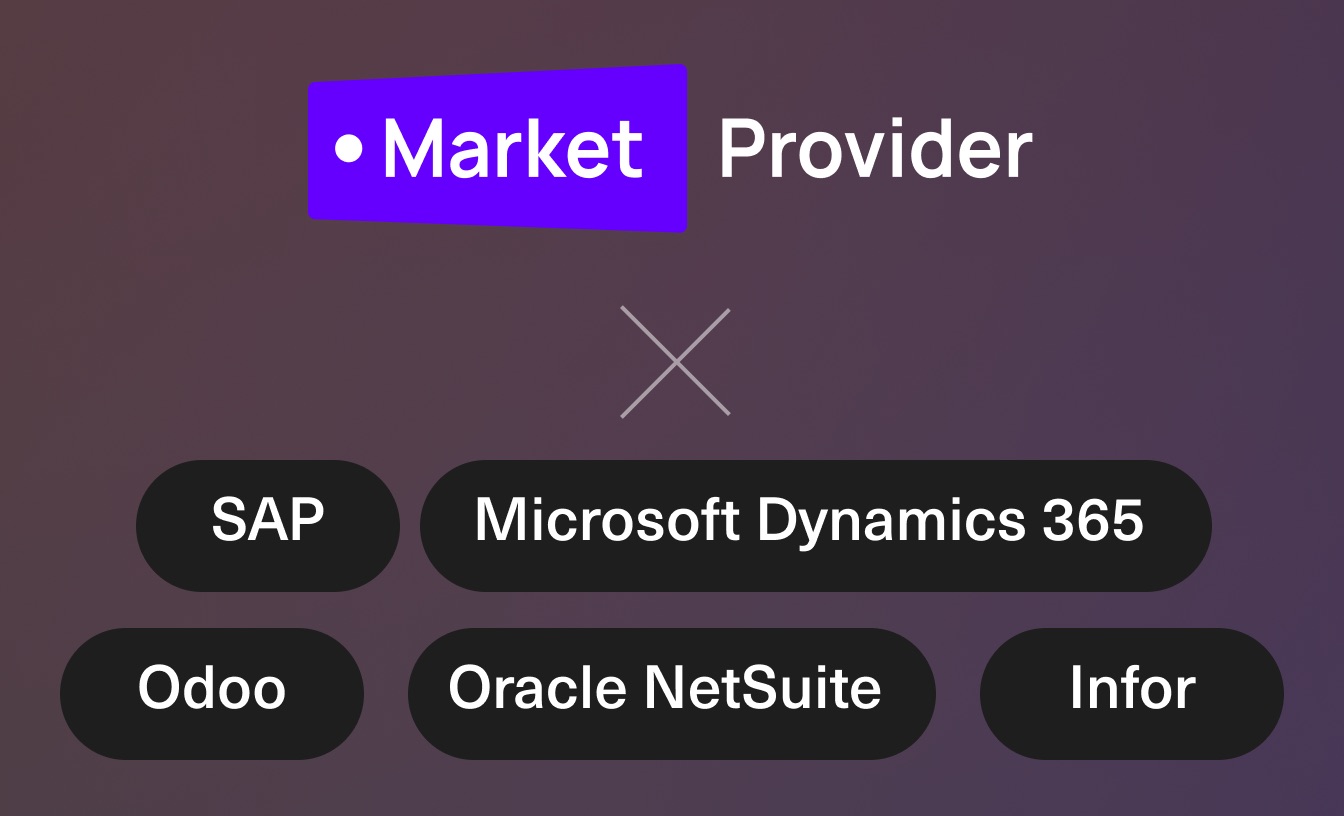

The most popular ERP systems:

- SAP — one of the largest ERP systems in the world, used by large corporations to manage all aspects of their business.

- Microsoft Dynamics 365 — a cloud-based ERP system integrated with other Microsoft products, suitable for businesses of any size.

- Odoo — a modular open-source ERP system popular among small and medium-sized businesses due to its flexibility.

- Oracle NetSuite — a cloud solution for managing finances, CRM, and e-commerce, widely used in international companies.

- Infor — an ERP system focused on specific industries such as manufacturing and retail.

ERP products represent a powerful tool for automating and managing business operations. Regardless of the industry and company size, ERP solutions help optimize processes, improve resource management, and comply with regulatory requirements. Flexibility, integration capabilities, and broad support make ERP one of the best choices for companies striving for efficient and modern management of their business processes.

The ERP platform allows for customization and adaptation of solutions to specific business needs. Regardless of the company's size, ERP can be configured to perform the necessary functions, whether it is a small business or a large industrial enterprise.

Some companies try to expand the functionality of the ERP system to perform the functions of a PIM system. However, this leads to many complexities and limitations. ERP is originally designed as a system for managing accounting and logistics processes. Attempts to make ERP a full-fledged PIM system require significant modifications and can lead to reduced performance and increased maintenance costs.

Just as a PIM system cannot replace an ERP system for managing finances and logistics, an ERP system cannot fully replace PIM in managing product data.

One of the key advantages of ERP is the ability to integrate with other systems and platforms.

This is especially important in modern conditions, where businesses use a variety of software solutions for different tasks.

Integration with PIM systems allows for more effective management of product data, optimizing business processes, and minimizing errors, as well as improving teamwork.

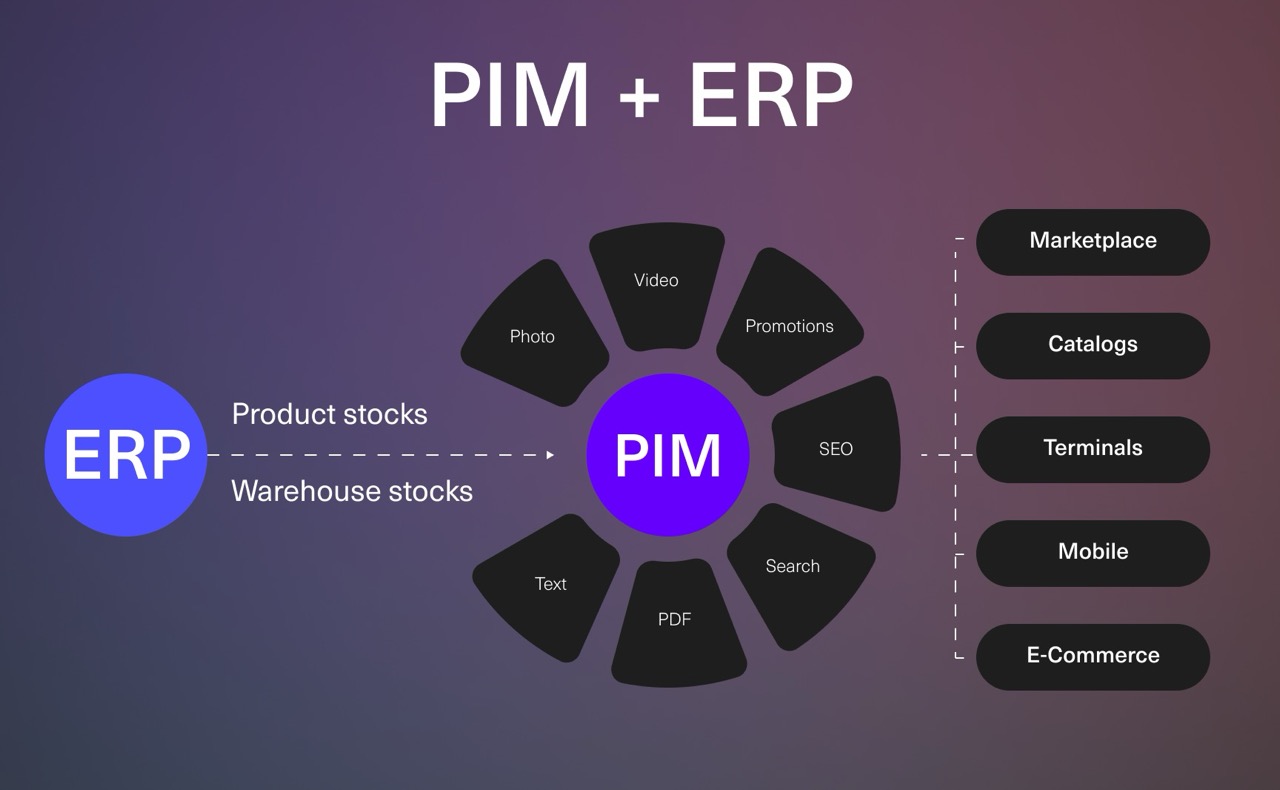

- PIM systems support the collection and centralized management of all product information, including photos, descriptions, technical specifications, prices, and availability.

- PIM automates data update processes, their transformation, and distribution across various sales and marketing channels.

- PIM systems are specifically designed for scalability and adaptation to different markets and segments, significantly simplifying their use in global companies.

- PIM systems easily adapt to various data standards and formats, such as XML or API, enabling efficient data management and integration with other systems, including ERP.

- Thanks to centralized management and access to a single source of data, PIM enhances teamwork and collaboration between different departments. Marketing, sales, and logistics teams can work with up-to-date and consistent information, increasing efficiency and reducing the risk of errors.

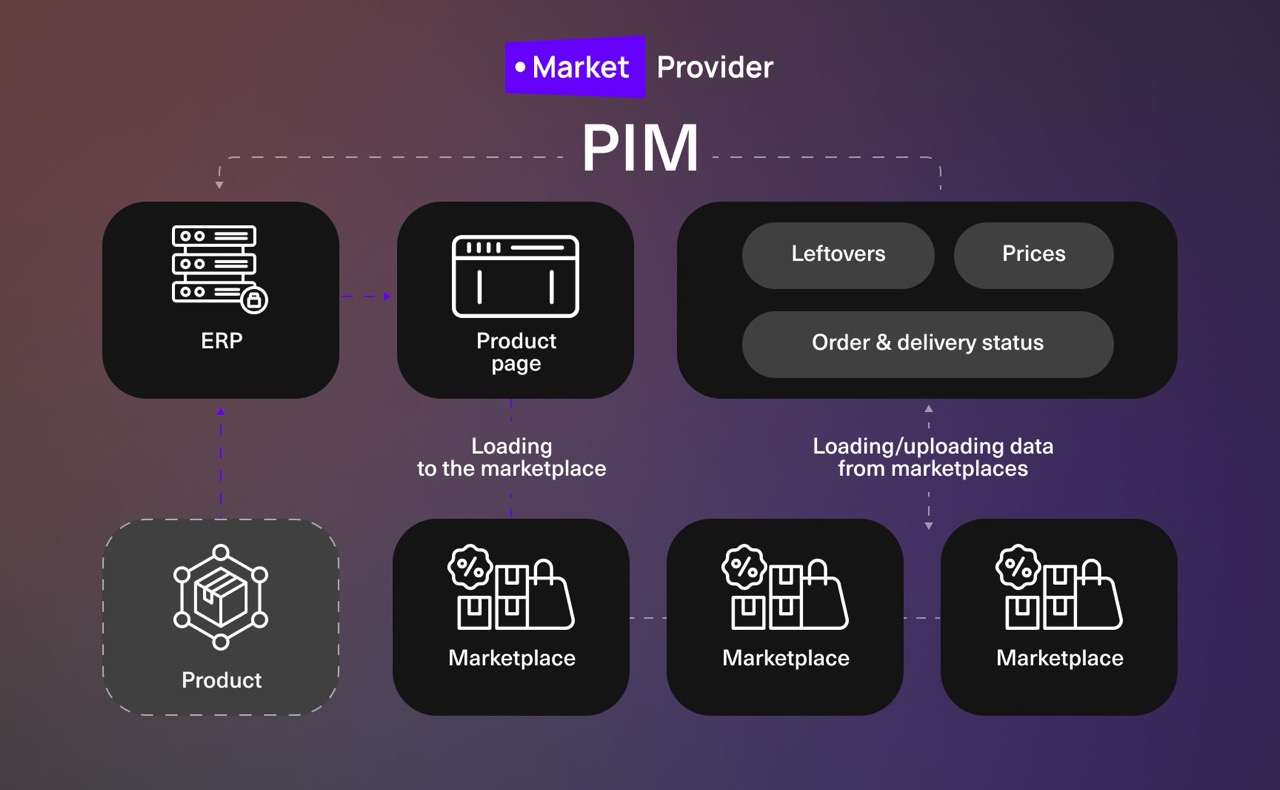

How the systems complement each other:

- The PIM system becomes the central hub for managing all product information, including descriptions, images, technical specifications, and prices. ERP, in turn, is responsible for managing accounting, inventory, and logistics.

- It is important to integrate the systems in a way that maximizes their complementarity. For example, PIM can automatically update product information, and ERP can use this data for accurate accounting and order processing. Together, they ensure high accuracy and relevance of data at all levels.

- Integration reduces the time to market for new products, automates data updates, and lowers the risk of errors. It's crucial to configure processes so that data is automatically transferred between systems, eliminating manual work.

- Any changes in ERP are automatically reflected in PIM and vice versa. This is critical for updating prices, stock availability, and other operational data that may change in real-time.

- When designing integration, it's important to consider that data can be transferred both sequentially and in parallel. Sequential data transfer is used when it's essential to maintain the order of data processing. Parallel data transfer accelerates data processing when different datasets are independent of each other.

ERP and PIM integration is a powerful solution that optimizes product data management and enhances business processes. It's important to integrate systems in a way that maximizes their complementarity, utilizing the full potential of each system.

Instead of trying to turn ERP into a PIM system, it's better to use specialized solutions for each task. This will not only increase data management efficiency but also improve the overall performance of the company by ensuring high accuracy and relevance of data at all levels of the business.

Configuring synchronization between ERP and PIM is an essential step toward automation and improved data management. Properly organized data exchange helps avoid errors, reduces the time needed to update information, and increases data accuracy at all levels of the business.

Effective synchronization allows integrating the two systems, using their strengths: ERP for accounting and logistics management and PIM for centralized management of product data and distribution across various sales channels. This not only optimizes business processes but also makes the company more successful and resilient in the market due to prompt updates and high data accuracy.

Following all stages of configuration, from requirement definition to testing and monitoring, will ensure the system's smooth operation and help you make the most of both ERP and PIM systems in your daily operations.

Companies that are already implementing PIM systems and integrating them with ERP gain a significant advantage in the market. They adapt faster to changes, respond promptly to customer needs, and have the ability to efficiently manage product data. This allows them to be more competitive, reduce costs, and minimize risks associated with inaccurate information.